Product Description

Caterpillar 249D Track Size

| Size | Width | Pitch | Links |

|---|---|---|---|

| 320x86x49 | 320mm | 86mm | 49 |

| 400x86x49 | 400mm | 86mm | 49 |

| - Guaranteed To Fit The Caterpillar 249D |

| - Premium Continuous Steel Cord Tracks |

| - Tracks Sold Individually |

Multi-Bar Pattern

The Multi-Bar pattern is designed to enhance the mobility and efficiency of your machine. This track features a distinctive pattern in multiple bars that run across the width of the track, offering unparalleled traction and durability in a variety of challenging terrains, including mud, sand, and rocky surfaces.

The multi-bar design ensures a larger contact area with the ground, significantly improving the stability and maneuverability of your equipment. This innovative pattern distributes the weight of the machinery evenly, reducing ground pressure and minimizing the risk of sinking in soft ground conditions. The result is a smoother, more controlled operation, which can lead to increased productivity and reduced wear on your machinery.

The Multi-Bar rubber track pattern distinguishes itself with enhanced flexibility, offering a smoother ride compared to some of our other tread patterns. This flexibility ensures optimal ground contact, absorbing shocks and reducing vibrations, leading to less operator fatigue and making it ideal for extended work periods across varied terrains.

Width Selection

When we offer multiple widths, either choice will fit your machine. Choosing the best width comes down to factors such as terrain, traction requirements, price, and space constraints.

Flotation

Wider tracks offer enhanced flotation by distributing the machine's weight over a larger area, reducing ground pressure and improving stability on soft or unstable terrain.

Traction

Traction is a critical aspect of machine performance, and in some conditions, it is improved by opting for narrower tracks.

Space & Machine Width

The decision to select a wider track also impacts the loader's overall width. Also consider the width of the attachment being used in relation to the track width.

Other Considerations

Narrow tracks cost less than wider tracks. However, wider tracks will not wear as quickly due to the fact that there is less pressure and more rubber.

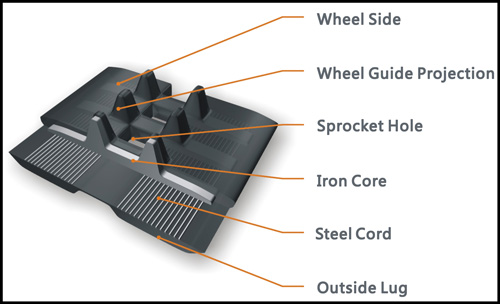

Premium Quality Tracks

- Drop Forged Steel Imbeds

- Wear Resistant Rubber Compounds

- Acid Washed Steel Cords

- Continuous Steel Cord Technology

- Second-to-none Rubber Bonding Technology

- Quality Control From Sourcing To Shipping

We understand that maintaining your equipment is an investment. And, when compared to other replacement tracks, our tracks provide the longest track life for the money ensuring the highest return on your investment.

*The product name is intended to describe the correct application and does not indicate affiliation or endorsement of the respective machine maker.