Product Description

|

|

|

|

Track Dimensions

| Width | Pitch | Links | |

| Standard (320x86x52) | 320mm | 86mm | 52 |

| Wide (400x86x52) | 400mm | 86mm | 52 |

| X-Wide (450x86x52) | 450mm | 86mm | 52 |

For more information on track dimensions and how to measure your track, please see our rubber track dimension guide.

Width Selection

When multiple track widths are listed, each width will fit your equipment. However, in most cases a standard width track is recommended. A more narrow track puts less tension on the track rollers and extends the life of the rollers and other parts which wear down from track pressure.

Wider tracks are often used when minimizing damage to the ground, or to extend the life of the track. A wide track distributes pressure over a larger surface area which causes less of an imprint in the the ground. For example, a wide track may prevent damage to a yard when digging a septic tank. Wider tracks also have a longer life due to more rubber in contact with the ground. When driving on an abrasive surface such as asphalt, a wide track may be used to extend the life of the track.

Block Tread

The staggered block tread is the most common pattern, and is often equipped on new track loaders from the factory. It is generally the most durable and is suitable for a wide range of applications. While performing best on hard surfaces, the block pattern works well on many terrains such as gravel, asphalt, dirt, mud, clay, or even sand.

The block pattern also has a larger rubber surface than other tracks which makes it preferable when trying to avoid damage to the ground. Block treads are considered to be a generable purpose tread while other patterns are designed for more specific applications.

Our Tracks

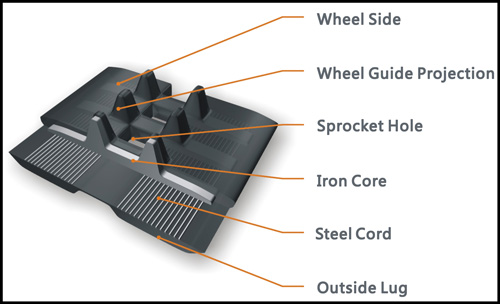

Our rubber tracks are of the highest quality and built for performance and durability. We use a trusted manufacturer with decades of experience in the rubber track industry. Each track is made with premium components and designed as an OEM quality replacement for your original tracks.

|

|

|